Wahfook

-----------Leader of core image system for drill core, cuttings, sidewall drilling core About

us

About

usWahfook, an innovative company specializing in total digital imaging solutions for core scan service more than 20 years, owning the ability to design and produce scan instruments to acquire the high resolution images in true color for drill core, cuttings, sidewall drilling core under both natural and fluorescent light; develop software suite to process core image and analyze core geological structures, to manage core image and textural data by setting up digital core library, Wahfook web platform is suitable for customized web system of comprehensive drill core information.

Wahfook also set up a professional onsite service team to provides turn-key core scan service for worldwide customers with in-house proprietary scanner and software.

Our

business

Our

business1. Custom made core scan device and core scan system;

2. Custom made software of core image management;

3. Selling Wahfook CoreImage® system;

4. Selling Wahfook CuttingsImage system;

5. Selling Wahfook fluorescent CoreImage system;

6. Selling Wahfook fluorescent CuttingsImage system;

7. Selling Wahfook CoreImage® web platform;

8. Service to scan core and cuttings at drilling site and core storage site;

9. Service to set up core image library ;

10. Service to set up core image web platform;

Vision

VisionTo be a step forward in providing one stop core scanner design, core image management system, core scan service, and technology implementation to our customer.

Our

value

Our

value• Specialization and Service

• In house scanner instrument, management system

• Continuous improvement and innovation

Contact us

Contact us• Contacts:Allan Chen

• Address:Beijing city Haidian District Shangdi information Road No. 2 Building 1 13E

• Telephone:(86)0716-4304861 18998001868

• E-mail:[email protected]

Wahfook CoreImage® system

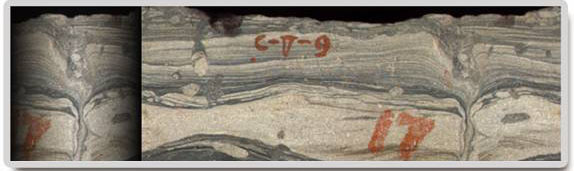

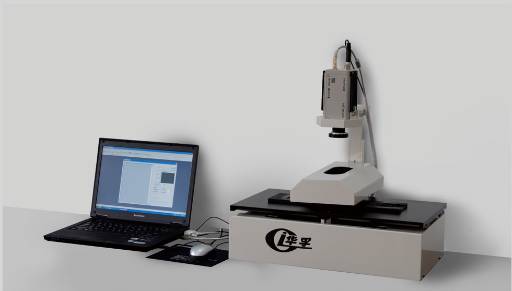

Wahfook CoreImage® system consist of two models of scanner instrument suitable for indoor and outdoor operation and software suite to implement the whole core scan process for acquisition , process ,evaluation and storage of core image and textural data. The system is very powerful to support the real time cooperative working for drilling site ( offshore and onshore) and remote office. Wahfook develop advanced compressed data technology favorable to fast transfer large core image data from international network and uncompressed data technology to restore core image data without display distortion. The system contribute to the virtual office for different teams working together from outdoor and indoor people.Wahfook CoreImage® Scanner YXCJ-VII

Wahfook CoreImage® scanner YXCJ-VII is designed for indoor operation in lab and drill core warehouse, The scanner can image full drill cores in full-circumference and slabbed core in true colour with a high resolution of up to 2400DPI with ultra linear scanning speed of1200 lines/second. In a single operation the scanner is able to scan sections of drill cores of 20 to 160 mm diameter up to 1000mm in length.

| Model No | YXCJ-VII |

| Dimension | 1200mm 420mm1270mm(L W H) |

| Weight | 98kgs |

| Core Diameter | 20mm~160mm |

| Core Length | 1000mm |

| Resolution | 350~2400DPI |

| Power Supply | 180v~260v,50HZ,350w |

| Working environment temperature | -35˚C~55 ˚C |

| Working environment humidity | 5%~80% |

Portable Wahfook CoreImage® Scanner YXCJB-VII

Wahfook CoreImage® scanner YXCJB-VII is a portable device designed for outdoor operation which is convenient to bring and operate at offshore drilling platform and onshore drilling site , The special mechnical design can support to scan drill core up to 1000mm in length even the scanner is shorter and lighter. The scanner is a folding device being folded into a suitcase when taking out for fields operation. By means of advanced compressed and uncompressed data technology, the core image acquired on fields can be transfered to server database fast via international network and accessed in real time by specialists who are working at remote office. The system implements real-time cooperative working for drilling site and indoor office in the worldwide.

| Model No | YXCB-VII |

| Dimension | 600mm 400mm 750mm(L W H) |

| Weight | 55KG |

| Core Diameter | 20mm~180mm |

| Core Length | 1000mm |

| Resolution | 350~2400DPI |

| Power Supply | 180v~260v,50HZ,350w |

| Working environment temperature | -35˚C~55 ˚C |

| Working environment humidity | 5%~80% |

Software suite

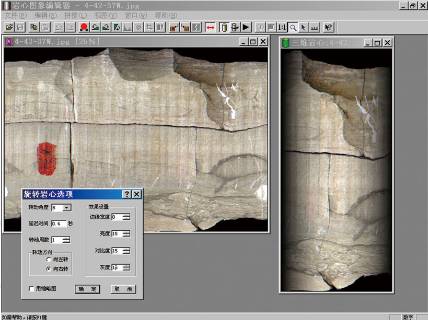

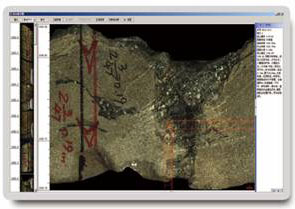

1. Wahfook CoreImage® processingWahfook CoreImage® processing is a powerful program to process acquired core image including below features :

(1) Image format support BMP,JPEG,TIFF,GIF,PCX,TGA,etc.

(2) The program provide wides of image process method to improve the quality of image display, like to adjust image brightness, saturation ,contrast, gray and distribution curve;

(3) The core image could be reviewed at different display scale and angle;

(4) The core image could be disconnected and connected automatically;

(5) Advanced compressed and uncompressed technology to reach compression ratio up to 1:30 for JPEG image; The compressed image data bring benefit to save and transfer the data fast;

(6) Drill core image is displayed as 3D scan and rotated randomly;

(7) The petrographical parameter like length, width, orientation and size could be measured from the grain size down to 0.1mm.

Core image connected automatically

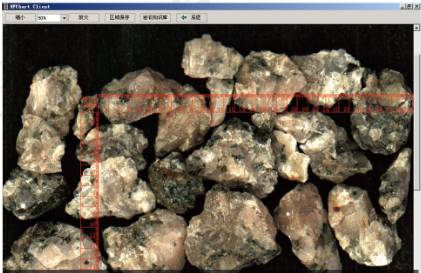

Grain measurement

3D scanning

2. Wahfook CoreImage® Analyzing

Wahfook CoreImage® Analyzing program utilize in combination with computer image processing, pattern recognition, mathematical statistics science knowledge to implement the functions to evalute and quantify the core petrographical properties , like fracture analysis, conglomerate analysis, rock hole analysis.

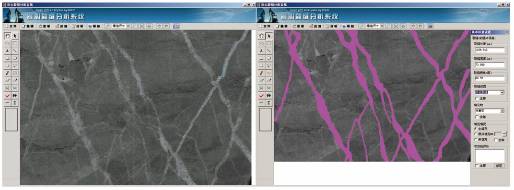

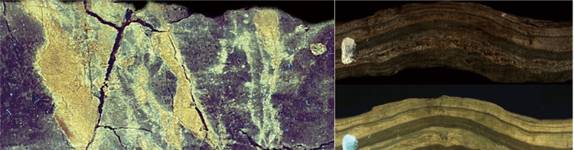

(1) Fracture analysis

The fracture analysis is a professional geological analysis process for below fracture features:

A. Fracture dimension measurement : to measure fracture length,width,obliquity ,fracture interval,fracture area;

B. Fracture properties analysis: to confirm fracture location, fracture genetic type,filling degree;

C. Fracture parameter statistics : to calculate fracture parameter,fracture linear density,fracture area density.

D. Fracture analysis report.

(2) Conglomerate analysis

The conglomerate analysis is mainly for grain analysis .

A. Grain dimension measurement : like to measure grain size,shape,diameter ,skewness,peakedness,.etc;

B. Grain properties analysis: grain psephicity,cementitious type and intensity;

C. Grain parameter statistics : to calculate the grain quantity,percentage of different diameter range; calculate average grain diameter,the median of grain diameter,standard deviation,separation factor;

D. Grain size distribution forecast: to forecast grain size distribution in three-dimensional grain size distribution;

E. Conglomerate analysis report.

(3) Rock hole analysis

Rock hole analysis implement quantitative evaluation of geological parameter to identify the development level of rock hole ;

A. Rock hole dimension measurement : hole long axis, short axis, equivalent circle’s diameter;

B. Rock hole properties analysis: fillings , filing level;

C. Rock hole parameter statistics : hole quantity, the hole size; plane porosity

D. Rock hole report

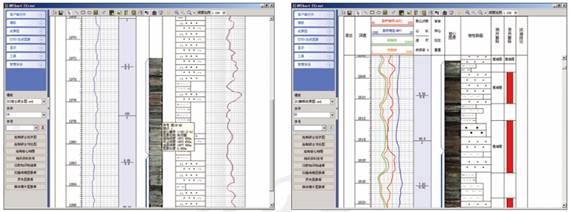

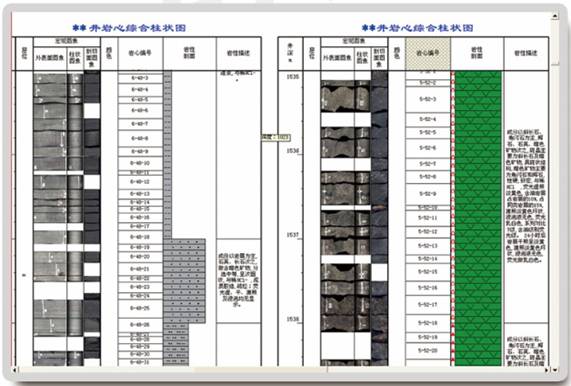

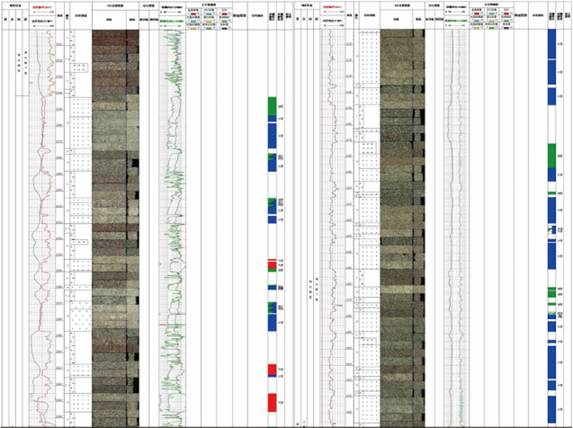

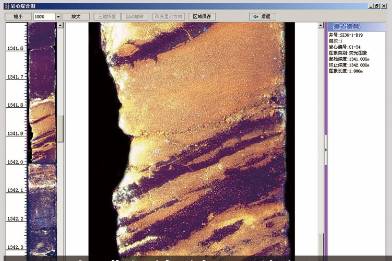

3. Wahfook CoreImage® Visualization

4. Wahfook CoreImage® Base.

Wahfook CoreImage® Base is a database system to manage and organize the core image , the data management system cover comprehensive information from borehole, drill core , textural features, reservoir data and sedimentary structure. It supports fast search to catch core image and multi-borehole comparision.

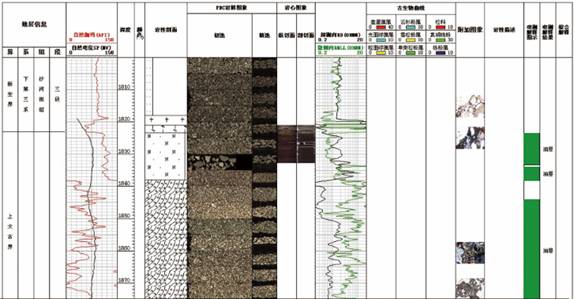

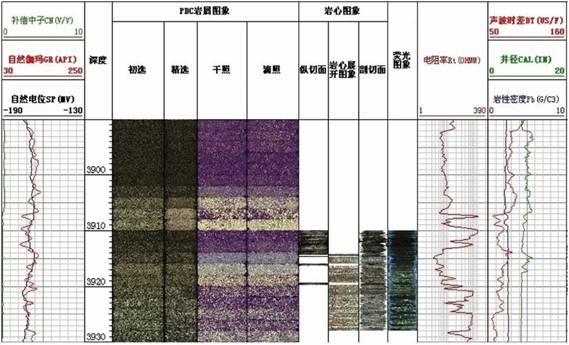

Multi-borehole comparision

Sedimentary structure knowledge database

Comprehensive borehole map

5. Wahfook CoreImage® web platform

Wahfook CoreImage web platform is a comprehensive platform to launch the core image base via internal network and internet with the outstanding features as below:

1. Comprehensive geological histogram drawing

2. Core image album display

3. Customized application model

4. Core image display, process and measure

5. Core image 3D display

6. Multi-borehole comparision

Wahfook CuttingsImage system

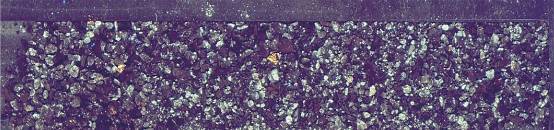

The process to get drill core is a high cost and time consuming process at the drilling industry, how to save cost and time to evaluate the borehole property without drill core has being become a challenge for a long time. Under the PDC drilling condition, plenty of cuttings from borehole can not be recorded quantifiably . The develops of Wahfook cuttings image scanner create an innovative means to acquire cuttings image along with the software suite to evaluate and record the borehole from PDC drilling cuttings.Wahfook CuttingsImage scanner PGPDC-II

| Model No | PGPDC-II |

| Dimension | 500mm 282mm350mm(L W H) |

| Weight | 25kgs |

| Cuttings width | 50mm |

| Resolution | 2000~3000DPI |

| Power Supply | 180v~260v,50HZ,350w |

| Working environment temperature | 5˚C~45 ˚C |

| Working environment humidity | 5%~60% |

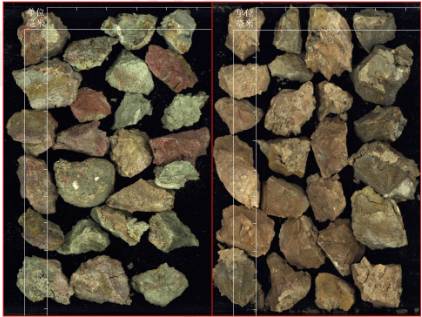

The cuttings image scanner is a portable design folded into suitcase for fields operation, Based on the wide fields service experience, Wahfook work out instruction on how to arrange, select and clean cuttings.

Working flow:

1. The steps to arrange, clean and sort cuttings

Step 1. Arranging and cleaning process: The method to arrange and clean cuttings is different for different type of rocks.Step 2. Initial samples sorting : To sort out 25% of cuttings from the whole cuttings sample bag based on the borehole logs.

Step 3. Deep samples sorting : To sort out the typical cuttings from initial samples in accordance with the rock type and color.

2. Cuttings image acquiring

The scanner will acquire images for both the initial samples and deep sorting samples.3. Cuttings image storage and visualization

Cuttings Image display

Cuttings Image visualization

Fluorescent CuttingsImage scanner YXCJ-II-YG

The cuttings still keep the oil-bearing signal even after the process from pressure reducing, degassing, washing by drilling liquids, Wahfook fluorescent cuttings image scanner will be very useful to acquire the oil-bearing information when cuttings out of borehole.

| Model No | YXCJ-II-YG |

| Dimension | 500mm 282mm350mm(L W H) |

| Weight | 25kgs |

| Cuttings width | 50mm |

| Resolution | 650DPI |

| Power Supply | 180v~260v,50HZ,90w |

| Working environment temperature | -35˚C~55 ˚C |

| Working environment humidity | 5%~80% |

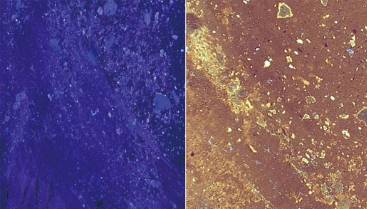

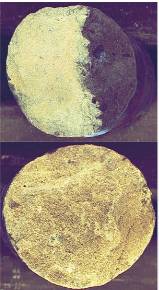

Fluorescent cuttings image display

Dry cuttings fluorescent image(up) and wet cuttings fluorescent image(down)

Fluorescent cuttings image onsite

PDC cuttings image visualization

Wahfook Fluorescent CoreImage® system

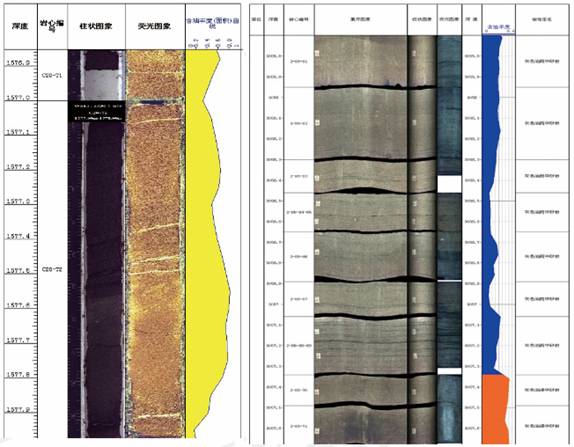

Wahfook design fluorescent CoreImage® scanner to acquire fluorescent image favorable for the quantitative analysis of oil- bearing property of drill core; The fluorescent scanner is a creative instrument to replace the traditional dark box to observe oil- bearing core at drilling site, The system provide the possibility to observe and evaluate the oil- bearing property from drill core, and keep the fluorescent image .Wahfook Fluorescent CoreImage® Scanner YGCJ-II

| Model No | YGCJ-II |

| Dimension | 600mm 400mm420mm(L W H) |

| Weight | 65kgs |

| Core Diameter | 40mm~160mm |

| Core Length | 1000mm |

| Resolution | 250DPI |

| Power Supply | 180v~260v,50HZ,90w |

| Working environment temperature | -35˚C~55 ˚C |

| Working environment humidity | 5%~80% |

The scanner is a portable device which could be folded into suitcase for outside operation, it is assembled with one fine definition broadcast 3CCD camera which could perform acquiring good quality fluorescent image under low lux( lowest to 0.1lumen) condition.

The fluorescent image display

From digital camera

From Wahfook scanner

The fluorescent core image process and analyze

The function to process and analyze fluorescent core image is embedded into Wahfook CoreImage® Processing and Wahfook CoreImage® Analyzing program.

(1) Fluorescent area measurement : the program measure the oil-bearing area automatically after processing the fluorescent image ;

(2) Oil-bearing properties analysis : To confirm oil-bearing property(thick oil ,thin oil,clean oil,residual oil after waterwashing),level of filling oil(full filled,filled in large area,partial filled),oil-bearing class(full filled oil,oil-bearing,fluorescence,oil stain,oil trace,oil immersion),bitumen content

(3) Fluorescent core image synthesis map

Jump to Chinese website